Xplore

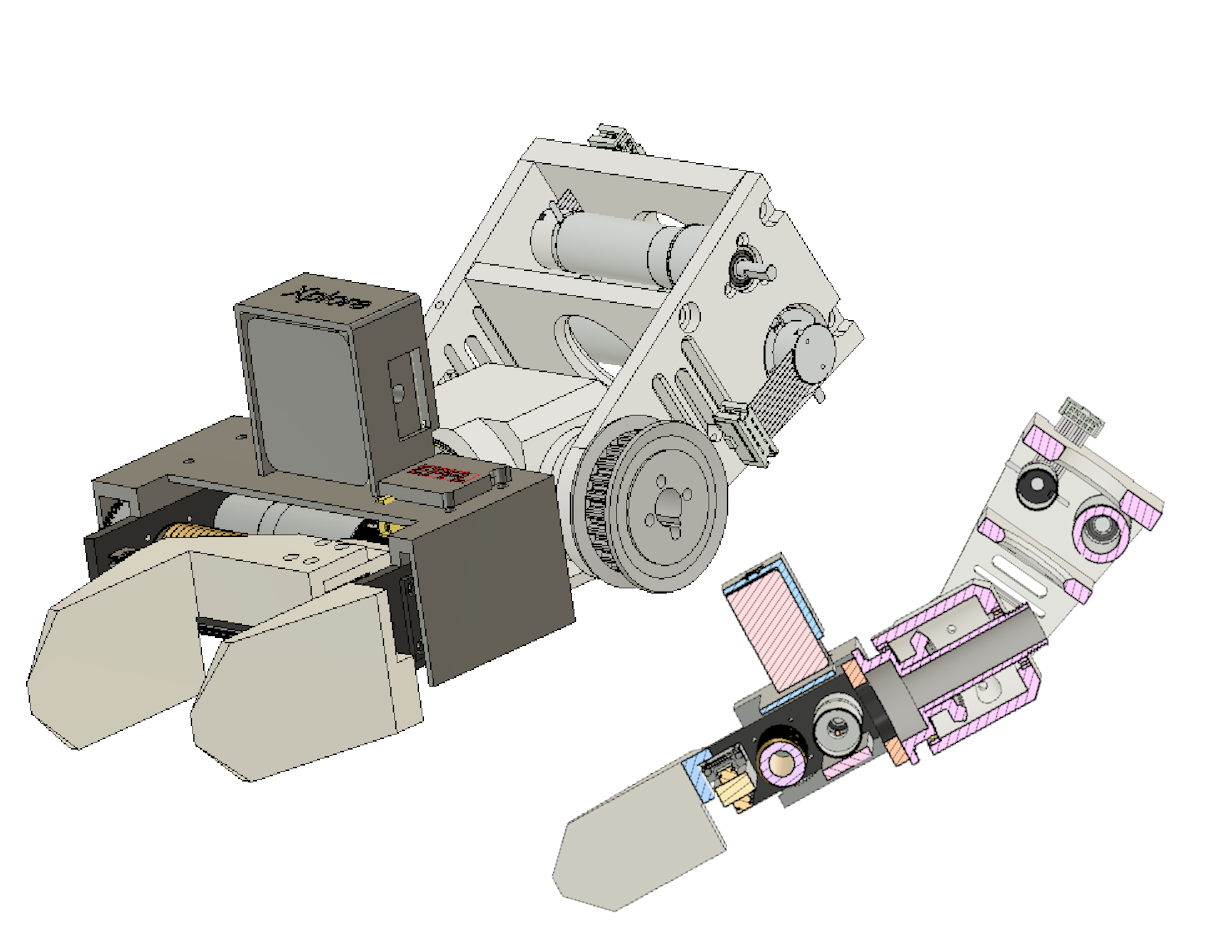

Design of robotic wrist and gripper, 2022

What I did

- Designed and prototyped a robotic wrist using differential belts

- Engineered a custom gripper with a "two way screw" mechanism for long stroke

What I learned

- Fusion360 proficiency, 3D printing

- Technical drawings, tolerances and norms

Outcome

- Working end effector, always grabing objects and hands at events :D

- 3rd place at the European Rover Challenge, and best manipulation award 🏆(certificate here) !

/>

/>

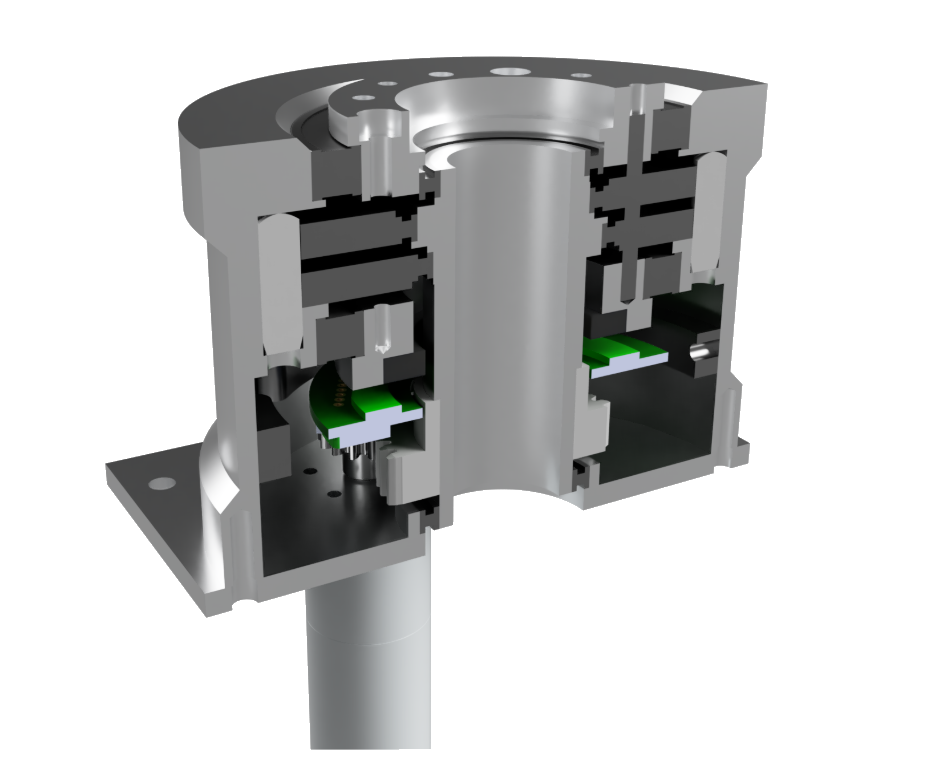

Design and manufacturing of a robotic joint, 2023

What I did

- Extensive litterature review of actuators and drives

- Design and manufacturing of a custom cycloidal drive for low backlash

- Design and manufacturing of a universal hollow robotic joint; integratting motor, drive and encoders

What I learned

- Solidworks and Inventor (some features were not in other softwares)

- Extensive knowledge on motors, drives, actuation types, encoders, controlers...

- Technical drawings respecting industrial standards

Outcome

- A robotic joint that is still used at Xplore because of its accuracy (sub mm), strenght, modularity and ease of use! 💪

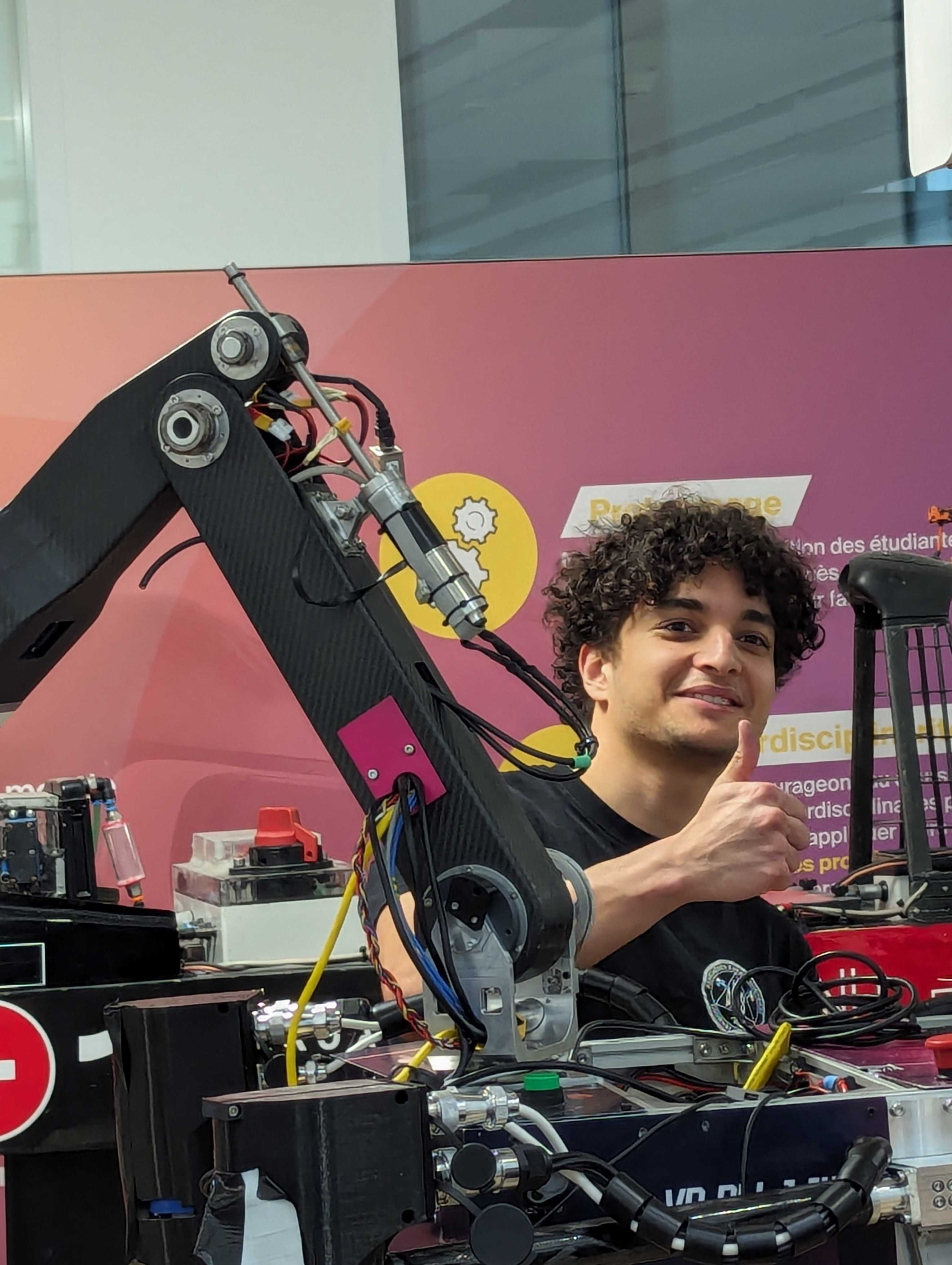

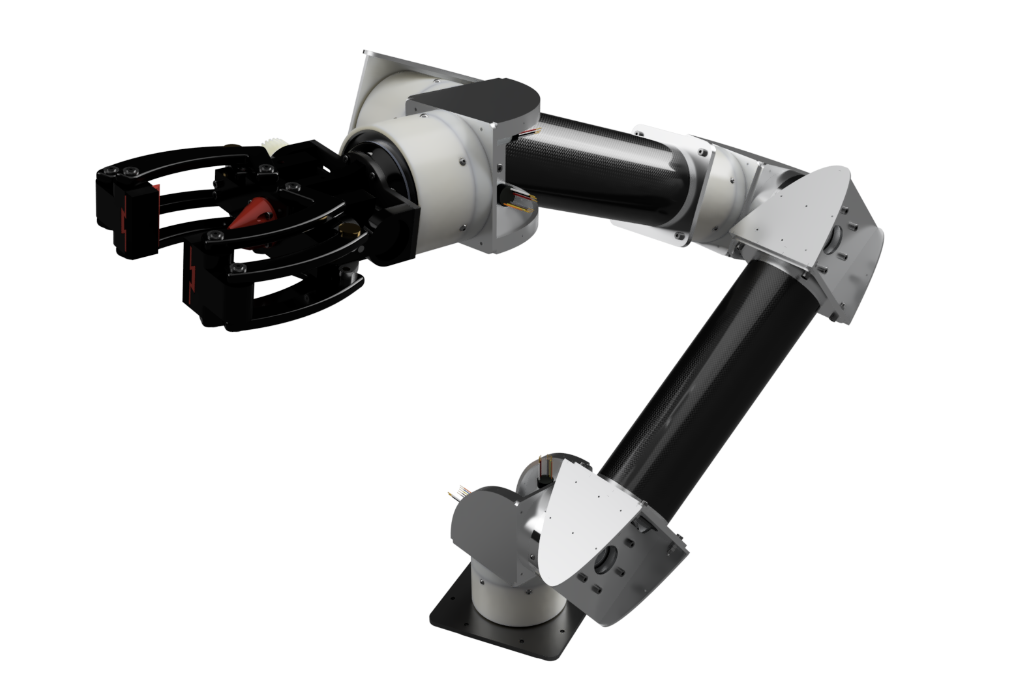

Design, manufacturing, assembly of a 6DOF robotic arm, 2024

What I did

- Managed a team of students to build a 6DOF robotic arm.

- Corrected all the parts and made them in a mechanical workshop.

- Assembled the arm and characterized it.

What I learned

- Team work, time management, budget managemnt, system engineering.

- Manufacturing: turning, milling, CNC, bending, soldering (TIG), SLA printing, crimping (cables, connectos), carbon fiber manufacturing

- Simulation: Abaqus and Ansys

Outcome

- A fully custom 6DOF arm that is still used at Xplore 🤩

Control and Inverse Kinematics, 2024

What I did

- Tuned all robotic joints in velocity and position; implemented a dual loop and feed-forward in position.

- Implemented Inverse kinematics for our specific arm architecture.

- Played with torque sensor outputs to create a compliant/transparent mode.

What I learned

- Applied control theory and Inverse Kinematics that I studied in class.

- Learned ROS2 (Humble), MoveIt and Rviz.

- Applied C++ and Python.

Outcome

- The arm was working well at the competition! (certificate here)

- It is still used everyday at Xplore and the team tries to impove the software.

- We tested features like compliant mode, but so much things are left to explore!

Spacecraft Team

Custom PCB for a CanSat, 2021

What I did

- With 3 friends, we engineered a little payload that was launched in a 2 meter size rocket.

- I was in charge of the electronics, so I designed the PCB.

What I learned

- Kicad, PCB design, Arduino, ESP32, STM32, sensors

- Aerodynamics, recovery systems, flight control

- Teamwork! Collaboration with other association (the RocketTeam)

Outcome

- Successful flight: CanSat launched, ejected, fins deployed, parachute deployed, landed where we launched it 🚀!!!

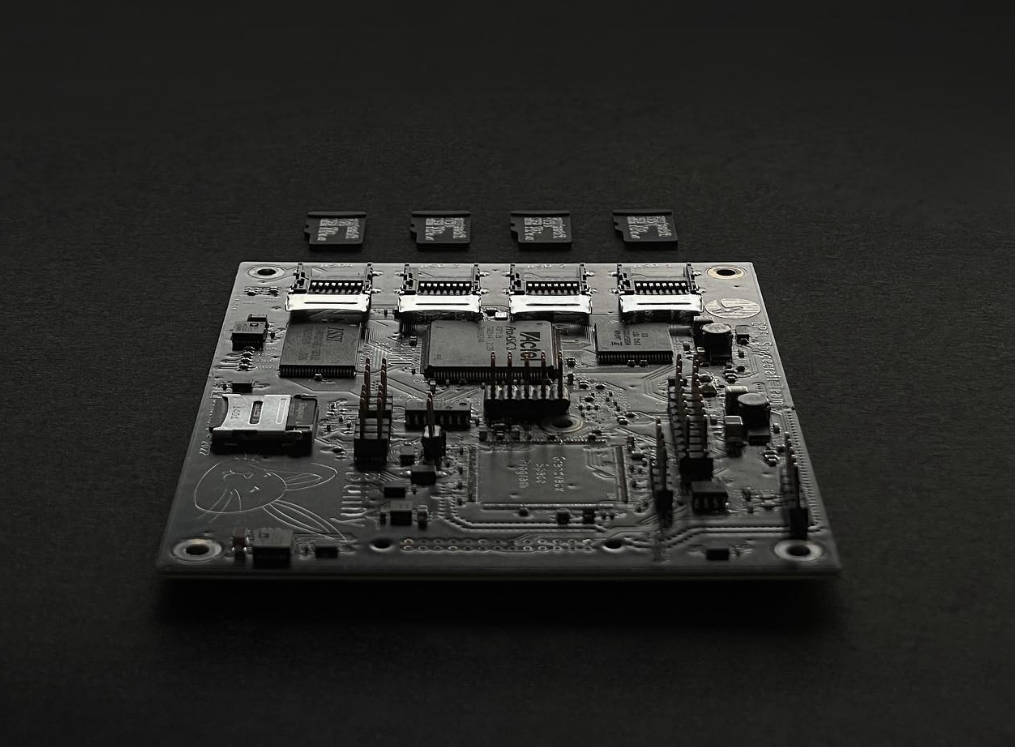

Onboard Computer for CubeSat, 2022

What I did

- I was one of the member working on the onboard computer we sent in Space.

- Integrated code to control power distribution within the OBC.

What I learned

- Power mangement, embeded systems, low level code.

- Space-grade electronics and protocols.

Outcome

- The board was succesfuly sent in Space and we are receiving data!

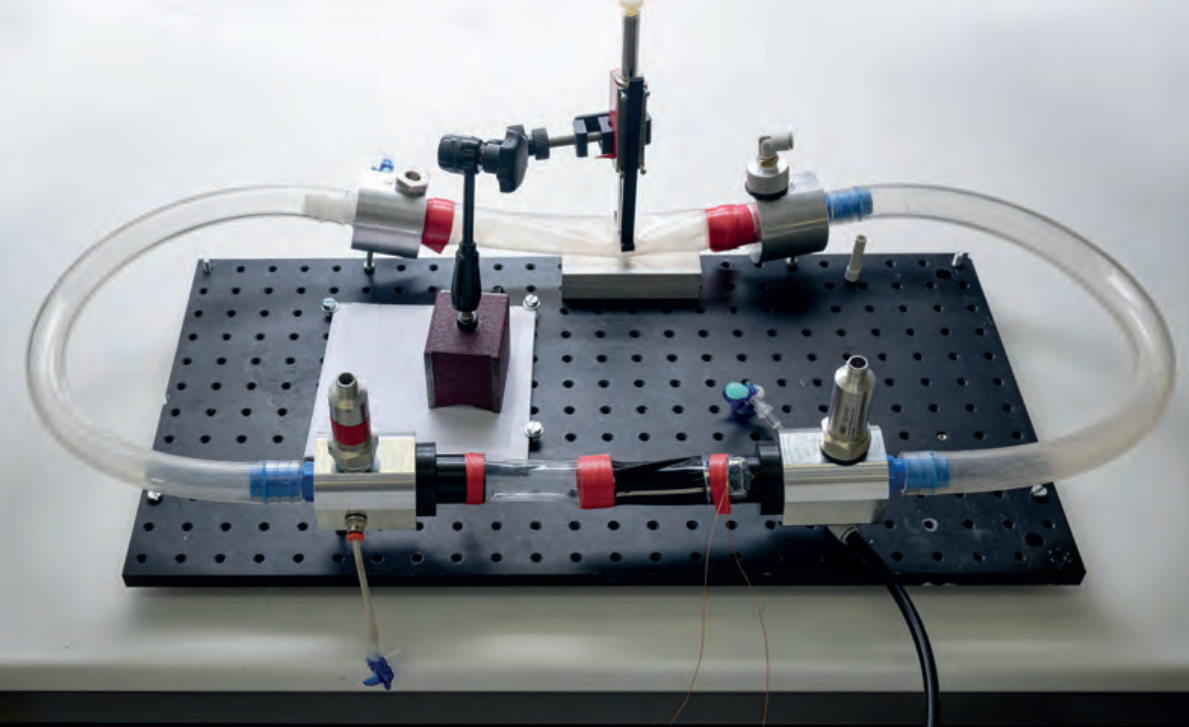

Design, Manufacturing and Optimization of an edible soft pneumatic artificial muscle, 2024

What I did

- Tried different geometries using optimization to maximize output force of an soft pneumatic actuator

- Tried lot of different mixtures of chemicals to improve the actuator's performances while being bio-compatible

- Characterized the actuator with motion capture, isobaric and isometric tests

What I learned

- Expertise in simulations with Comsol and Ansys: non linear and hyperelastic mechanics, fluids, thermodynamics, chemical reactions...

- Matlab and optimization toolboxes

- Soft robotics: bio-compatible materials, silicon manufacturing, advanced molding, chemistry

- writing publication for high impact conferences

Outcome

- The final actuator demonstrated a significant progress, with its characteristics improving by a factor of 40 compared to the initial version.

- Publication in IROS pending!

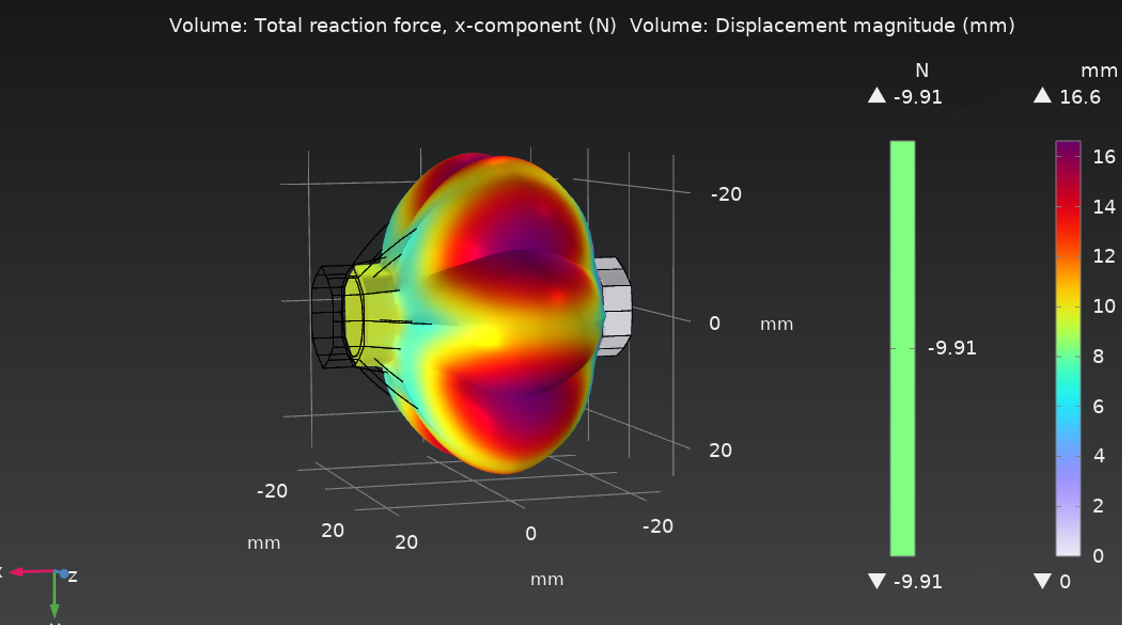

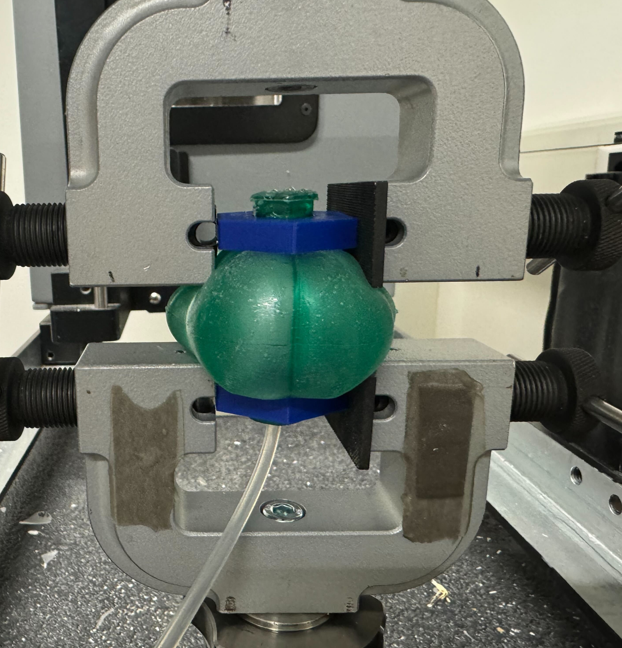

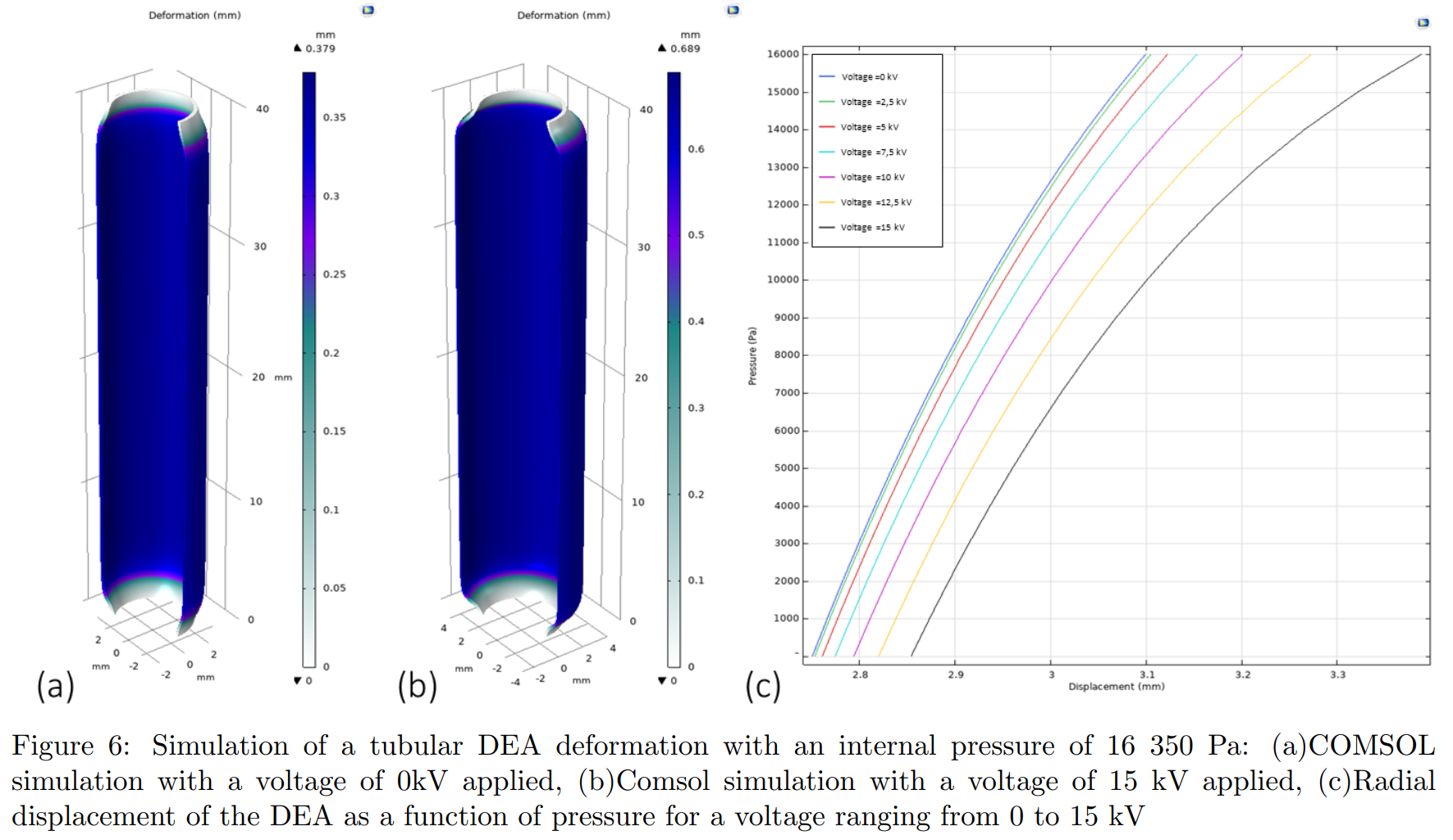

Optimization and Manufacturing of a dielectric elastomer artificial muscle, 2023

What I did

- Optimized a pre-existing dielectric elastromer technology to be applicable for medical uses

- Manufactured prototypes in cleanroom

What I learned

- Multiphysics simulations on Comsol: non-linear mechanics, fluids, electromagnetics, electrostatics...

- Cleanroom manufacturing and protocols

- A lot of knowledge on the human body and about medical standards and norms

Outcome

- Unofrtunately I showed that the dielectric elastomer technology was not performant enough (yet) for their application

- (They stopped the project...)

- We did a publication in a conference about this work (publication here)

Drone integration in a wildfire monitoring system, 2024

What I did

- Learned DJI SDK and the software "Pantera" of the startup (their website here)

- Used ROS + Gazebo to create a simulation of drone missions to take footage of wildfire

- Deployed little proof of concept offline on DJI hardware

What I learned

- Experience with ROS, Gazebo, Linux, FastAPI

- Experience with drone devellopment and DJI hardware

- Work with different teams, sometimes remotely

- C# and windows application (sdk) devellopment

Outcome

- Proved that DJI Mavic drones were easily integrable with the startup eco-system "Pantera"

- Really progressed in Portuguese!

(Note: The start-up does not want me to use content that is not already on the web, sorry)

I like music and specialy to play the piano!

I like running!

I like participating in hackathons!

I like karate!

I don't have cool pictures yet despite my 15 years of practice